iron iron carbide phase diagram

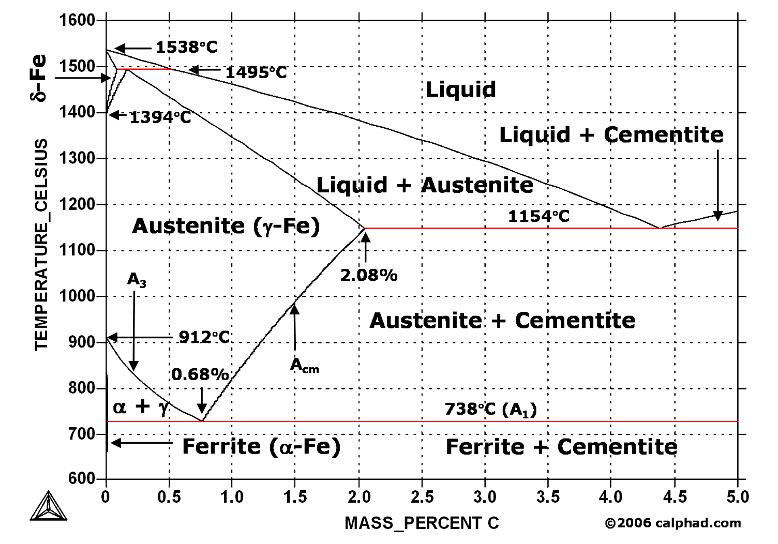

This colorless gas is widely used as a fuel and a chemical building block. It has maximum solubility of carbon of 009 at 1495C.

Iron Carbon Phase Diagram Diagram Quizlet

Titanium dioxide TiO2 is an important photocatalytic material that exists as two main polymorphs anatase and rutile.

. Its usefulness derives from its relatively low melting temperature. This trait is shared by indium cadmium zinc and mercury in the solid state. The sound power produced by the earphone came solely from the radio waves of the radio station being received intercepted by the antenna.

Being about twice the diameter of the tetrahedral hole the carbon introduces a strong local strain field. Stainless steels that are corrosion- and oxidation-resistant typically need an additional 11 chromiumBecause of its high tensile strength and low cost steel is used in. ASCII characters only characters found on a standard US keyboard.

IDM Members meetings for 2022 will be held from 12h45 to 14h30A zoom link or venue to be sent out before the time. Stannum and atomic number 50. Hydrogen peroxide is a chemical compound with the formula H 2 O 2In its pure form it is a very pale blue liquid that is slightly more viscous than waterIt is used as an oxidizer bleaching agent and antiseptic usually as a dilute solution 36 by weight in water for consumer use and in higher concentrations for industrial useConcentrated hydrogen peroxide or high-test peroxide.

When it dissolves in iron carbon atoms occupy interstitial holes. Mild steel carbon steel with up to about 02. White cast iron has carbide impurities which allow cracks to pass straight through grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks.

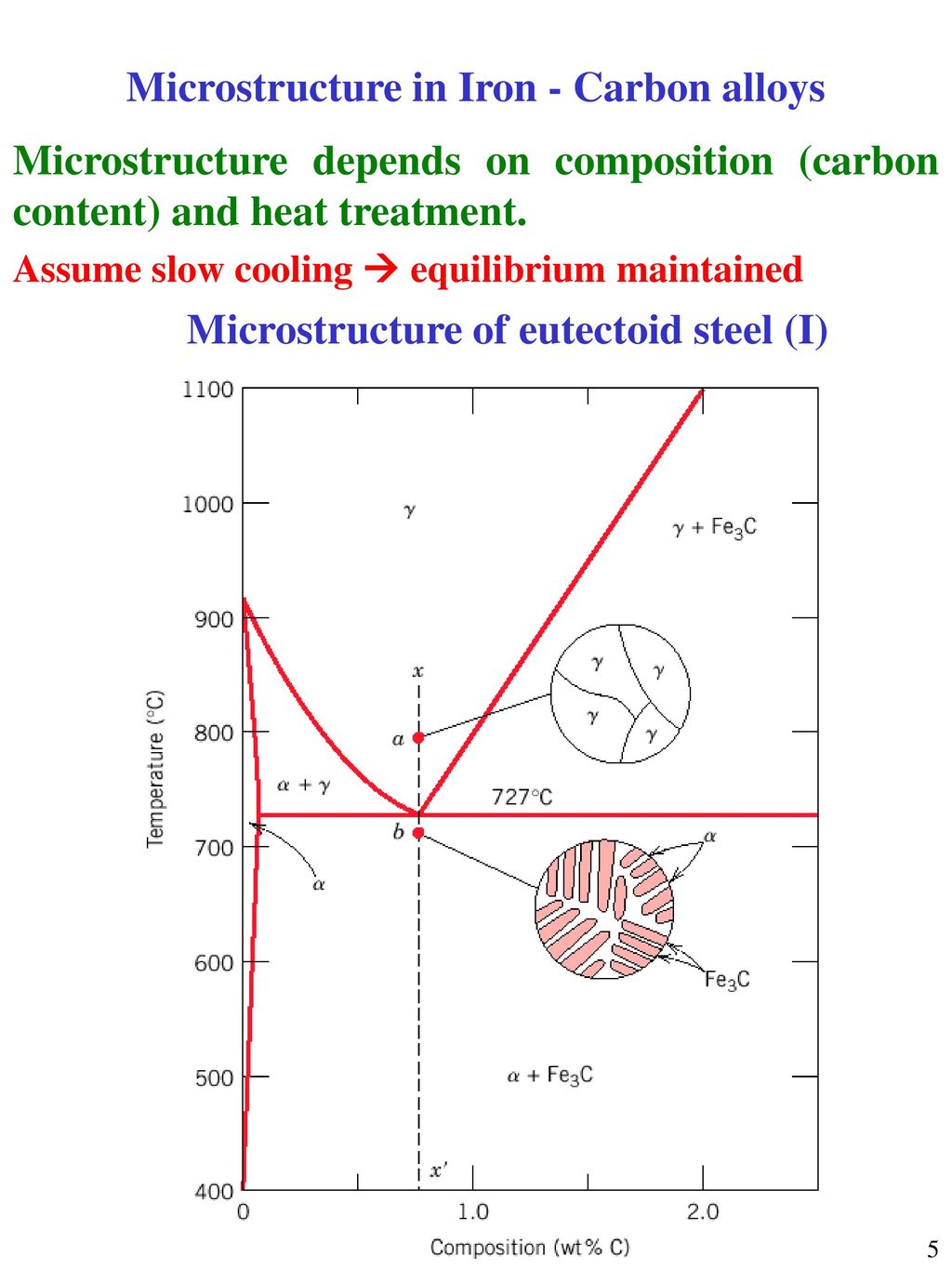

Austenite is stable only above 1333 degrees F. Tin is soft enough to be cut with little force and a bar of tin can be bent by hand with little effort. A graphic representation of the equilibrium temperature and composition limits of phase fields reactions in an alloy system.

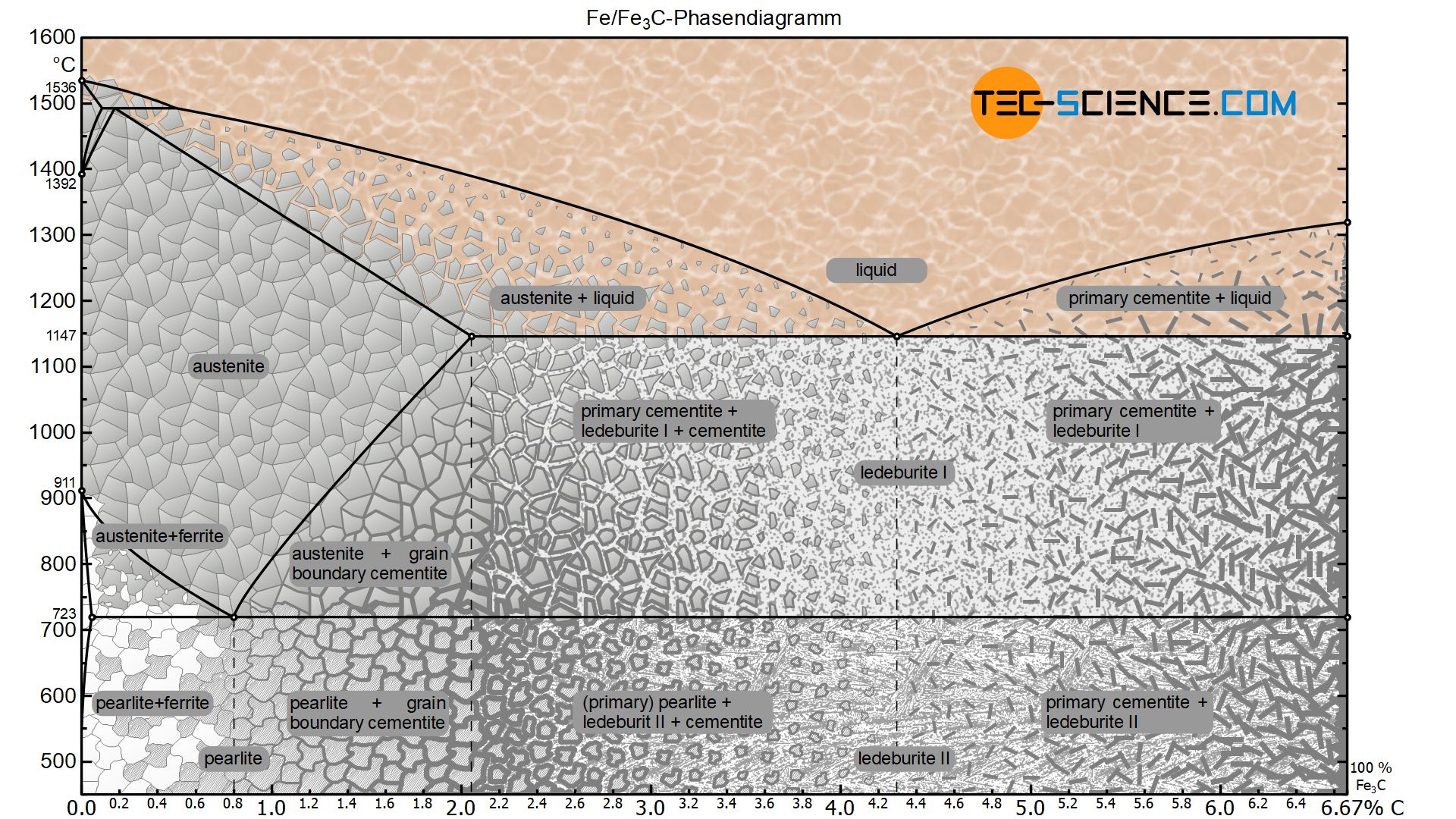

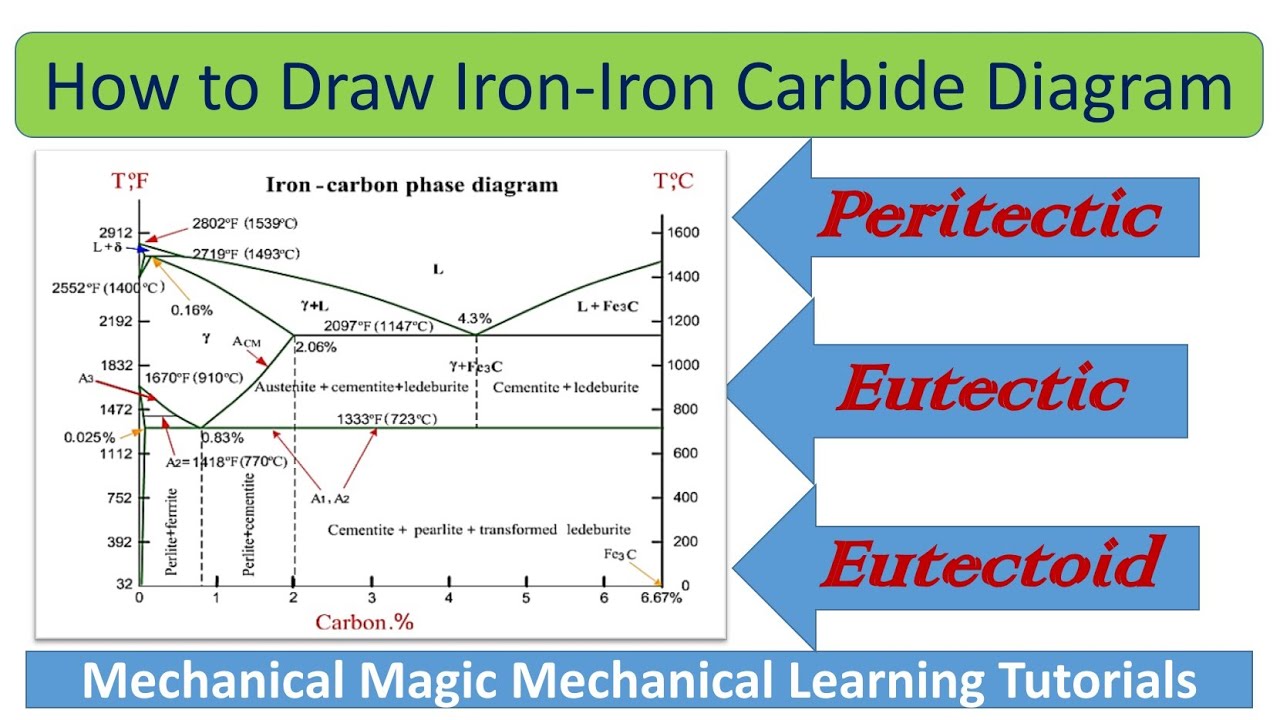

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 10 and 50 by weight to improve its mechanical propertiesAlloy steels are broken down into two groups. The Iron carbon equilibrium diagram also called the iron carbon phase diagram is a graphic representation of the respective microstructure states of the alloy iron carbon Fe-C depending on temperature and carbon content. When bent the so-called tin cry can be heard as a result of twinning in tin crystals.

Cementite or iron carbide is a compound of iron and carbon more precisely an intermediate transition metal carbide with the formula Fe 3 C. Must contain at least 4 different symbols. Such steels are known as austenitic.

Ethyne is the chemical compound with the formula C 2 H 2 and structure HCCHIt is a hydrocarbon and the simplest alkyne. The primary phase of low-carbon or mild steel and most cast irons at room temperature is ferromagnetic α-Fe. The presence of either or both of these phases impacts on the photocatalytic performance of the material.

Crystal radios had no amplifying components to increase the loudness of the radio signal. 723 C on the metastable iron-carbon phase diagram. Follow microstructural development in Cast Iron types to learn about graphite nucleation mechanism lediburite formation and eutectic and eutectoid reactions within cast iron.

Solid liquid and gas as well as. It is unstable in its pure form and thus is usually handled as a solution. Tin is a silvery-coloured metal.

Compulsory 2 marks will be given from this Iron-Carbon Diagram Theory in any exam. Iron Carbon Equilibrium Diagram. It is an interstitial intermediate compound having a fixed carbon content of 667.

The broken surface of a white cast iron is full of. Iron-Carbon Phase Diagram with Detailed Explanation. Cast Iron is considered the most widely used metal-matrix composite from the 1920s.

Low alloy steels and high alloy steels. The synthesis and properties of anatase and rutile are examined. Smith and Hashemi define the difference at 40 while Degarmo et al define it at 80.

Mechanical properties are difficult to obtain. Boilers water conduit pipes in Oil and Gas Industry. Austenite Phase in certain steels characterized as a solid solution usually of carbon or iron carbide in the hamma form of iron.

Pure acetylene is odorless but commercial grades usually have a marked odor. Tin is a chemical element with the symbol Sn from Latin. A phase diagram in physical chemistry engineering mineralogy and materials science is a type of chart used to show conditions pressure temperature volume etc at which thermodynamically distinct phases such as solid liquid or gaseous states occur and coexist at equilibrium.

If the percentage of the carbon is in the range of 0 to 211 then it is called Steel and if the percentage of carbon is in the range of 211 to 667 then it is called Cast iron. Therefore the sensitivity of the detector was a major factor determining the sensitivity and reception range of the receiver motivating much. Types of steels and alloys.

White cast irons contain their carbon in the form of cementite or iron carbide Fe 3 C. Cast Iron is being used in a wide area of industry ie.

In chemistry thermodynamics and many other related fields phase transitions or phase changes are the physical processes of transition between a state of a medium identified by some parameters and another one with different values of the parameters. Heat treating or heat treatment is a group of industrial thermal and metalworking processes used to alter the physical and sometimes chemical properties of a materialThe most common application is metallurgicalHeat treatments are also used in the manufacture of many other materials such as glassHeat treatment involves the use of heating or chilling normally to. High-energy ball milling has been demonstrated as a powerful method to cut and reconstruct the.

In a binary system. The iron carbon phase diagram is commonly used to fully understand the various phases of steel and cast iron. Ferrite is the softest structure on the iron-iron carbide diagram.

Cementite is characterized by an orthorhombic crystal structure. Recent review by Bhadeshia provided the following. Iv Cementite Iron Carbide Fe 3 C.

The difference between the two is disputed. A compound of iron and carbon commonly known as iron carbide and having the approximate chemical structure Fe3C. The alloy constituents affect its color when fractured.

This hard brittle compound dominates the mechanical properties of white cast irons rendering them hard but unresistant to shock. Ferrite acts magnetically at low temperatures but its magnetic properties are dethatched once its temperature rises and above 786C temperature it becomes non-magnetic. It is a high temperature phase and is a high temperature manifestation of a-ferrite.

α-Iron is a. Here we report one strategy to achieve a highly dispersed single FeN 4 center with CUS Fe sites confined in a graphene matrix at a large quantity via high-energy ball milling of iron phthalocyanine FePc and graphene nanosheets GNs under controllable conditions. The present work reviews the anatase to rutile phase transformation.

Commonly the term is used to refer to changes among the basic states of matter. It is an interstitial solid solution of carbon in delta iron having BCC structure. Many other elements may be present or added.

Steel is an alloy made up of iron with typically a few tenths of a percent of carbon to improve its strength and fracture resistance compared to other forms of iron. In a plain carbon steel but the presence of certain alloying elements such as nickel and manganese stabilizes the austenitec. 6 to 30 characters long.

It has a hardness of approximately 80 Brinell. By weight it is 667 carbon and 933 iron. The ironiron carbide FeFe 3 C phase diagram.

Cast iron is a class of ironcarbon alloys with a carbon content more than 2.

Determination Of Microstructure And Phase Fractions In Steels Tec Science

What Is The Use Of An Iron Carbide Phase Diagram Quora

The Iron Iron Carbide Fe Fe3c Phase Diagram Ppt Download

Phase Diagram Iron Carbon Metallurgy For Dummies

Iron Carbon Phase Or Equilibrium Diagram Or Iron Carbide Diagram Mechstudies Com

Iron Carbon Phase Diagram Project Factory

1 The Iron Iron Carbide Phase Diagram Adapted From Binary Alloy Phase Download Scientific Diagram

Practical Maintenance Blog Archive The Iron Iron Carbide Equilibrium Diagram

How To Draw Iron Carbon Diagram Iron Carbon Diagram Explained Iron Carbon Diagram Youtube

Cast Iron 9 5 1 General Remarks

Iron Carbon Phase Diagram

Iron Iron Carbide Phase Diagram 6 7 Download Scientific Diagram

Welding Hardfacing Cladding And Cutting Of Metals Reading The Iron Carbon Phase Diagram

Iron Carbon Phase Diagram Explained With Graphs

7 Iron Carbon Phase Ideas Iron Carbon Mechanical Engineering

Gate Ese How To Remember Iron Carbon Phase Diagram Offered By Unacademy

Below Is An Equilibrium Diagram For An Iron